Company Fined! Inoperative Risk Assessment Procedures

This is the headline that covers almost half of the “Latest News” articles snippets on DMIRS website. Even though most of these cases that have now been settled through the courts are associated with incidents that happened years back, some have lead to fatalities, and they’re not likely to stop happening.

It all comes down to control measures and risk assessments. But since every plant has those and does those, it must be about more than that.

A culture shift from “production” to “safe production” is required.

How is your company’s risk assessment? Does it include structure integrity?

What about how it’s performed? Does your team know how to recognise risks before they become issues? Is there a supportive environment in which to report and action such risks?

Recognizing Risks

As structural engineers, I have to admit we assume a lot of non-structural engineers have knowledge about structures that we take for granted. It’s not the case. I guess a doctor would think the same thing if he saw somebody with a clear symptom that was being ignored. “Why wouldn’t he get that looked at?” would likely be his thought.

The truth is, we have our own skills so it’s not fair that we expect others to have them too..

One of our structural engineers conducting an inspection

Risk assessments should be carried out by people qualified to recognise and action the risk. And since there are many risks, there should be many people with various skills carrying out risk assessments

Risk Assessment Procedures

Control measure and risk assessment procedures are proactive processes that can help you respond to change and facilitate continuous improvement of your work environment.

These processes should be planned, systematic and cover all reasonably foreseeable hazards and associated risks.

A risk assessment involves considering what could happen if someone is exposed to a hazard (for example, fall from height) and the likelihood of it happening. This can then help you determine:

How severe a risk is

How severe a risk is

Whether any existing control measures are effective

Whether any existing control measures are effective

What action you should take to control the risk, and

What action you should take to control the risk, and

How urgently the action needs to be taken.

How urgently the action needs to be taken.

If a risk is foreseen, it must then be assessed and managed in the context of the operating environment.

A risk assessment can be undertaken with varying degrees of detail depending on the type of hazard and the information, data and resources that you have available. It can be as simple as a discussion with your workers or involve specific risk analysis tools and techniques developed for specific risks or recommended by safety professionals.

Risk Management Process (Image courtesy of SafeWork NWS)

When To Do a Risk Assessment?

Managing work health and safety risks is an ongoing process that needs attention over time, but particularly when any changes affect your work activities.

Risks need to be assessed and mitigated with consideration to the characteristics of the workers and their workplaces. This includes ensuring vulnerable people and structures are well protected and maintained to mitigate the foreseen hazards and maintain compliance.

Other examples of when a risk assessment MUST be undertaken include:

when responding to new concerns raised by workers

when responding to new concerns raised by workers

When new incident alerts are reported within the industry

When new incident alerts are reported within the industry

after changes in work practices and procedures

after changes in work practices and procedures

when planning to increase work operations

when planning to increase work operations

Risk assessments should be reviewed periodically as the operating environment changes, this ensures that the control measures set in place are appropriate and effective.

How to Do a Risk Assessment?

A safe and healthy workplace does not happen by chance or guesswork. You have to think about what could go wrong at your workplace and what the consequences could be. Then you must do whatever you can (in other words, whatever is ‘reasonably practicable’) to eliminate or minimise health and safety risks

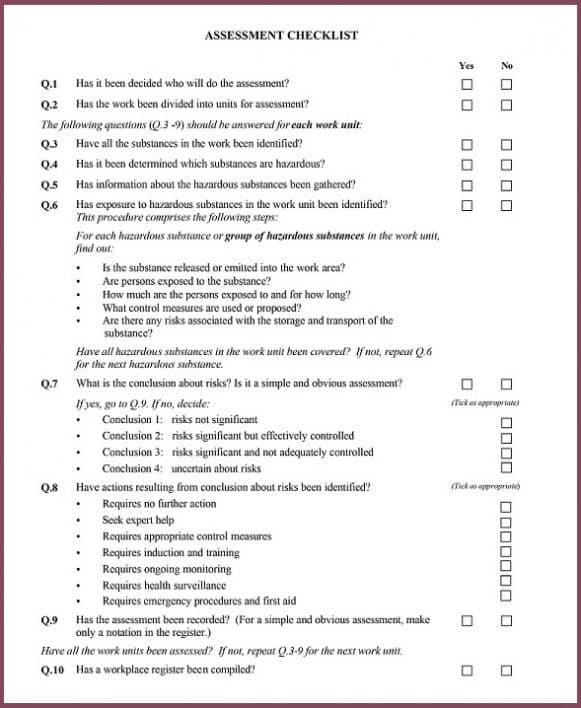

Following DMIRS “National Guidance Note for The Assessment of Health Risks“, the process should involve the following steps:

Workplace Managers:

-

- Decide who will do the assessment

- Divide the work into units for assessment

- Identify & determine hazardous substances around your workplace

- Obtain information about the hazardous substances (Safe Works Australia or DMIRS)

Outside Consultants:

-

- Inspect workplace and evaluate hazardous exposure

- Evaluate the risk

- Identify actions required from conclusions about risks

- Record the assessment

- Review the assessment (this should be done together with the workplace managers)

Risk Assessment Checklist, courtesy of National Occupational Health and Safety Commission

Consultation with workers around your workplace is paramount in the risk management process. By drawing on the experience, knowledge and ideas of your workers, you are more likely to identify all hazards and choose effective control measures.

Our Interactive 3D Video Reports

We’re not exactly known for doing things the ‘regular’ way!

A ‘regular’ structural inspection involves a site visit by a (hopefully) structural engineer, a thorough inspection of all things visible and accessible, and the all-important report – a behemoth of findings in a PDF document that even 5G will take ages to deliver!

Instead of said report constructed on an unwieldy spreadsheet, or a PDF document hundreds of pages long, you might prefer something like this. It’s a visual report of issues that makes it blatantly obvious what needs to be done and when:

Definitely get in touch if you want your structures professionally assessed and your reports prepared this way to ensure you’ve minimised your risk of structural issues on your site or your client’s site.

The post Company Fined! Inoperative Risk Assessment Procedures appeared first on Yenem Engineering Services.

Go to Source

Author: Dave Meney